Inventory management is the process of keeping track of and controlling the quantity of inventory a business has on hand. This process can be manual or automated, but most businesses use some combination of both.

The goal of inventory management is to ensure that a business has enough inventory to meet customer demand, without having so much that it ties up too much capital. The key to successful inventory management is to strike a balance between these two extremes.

An inventory control system is a system that helps businesses keep track of their inventory. There are many different types of inventory control systems available, each with its own advantages and disadvantages. The most important thing to consider when choosing an inventory control system is what type of business you have and what your specific needs are.

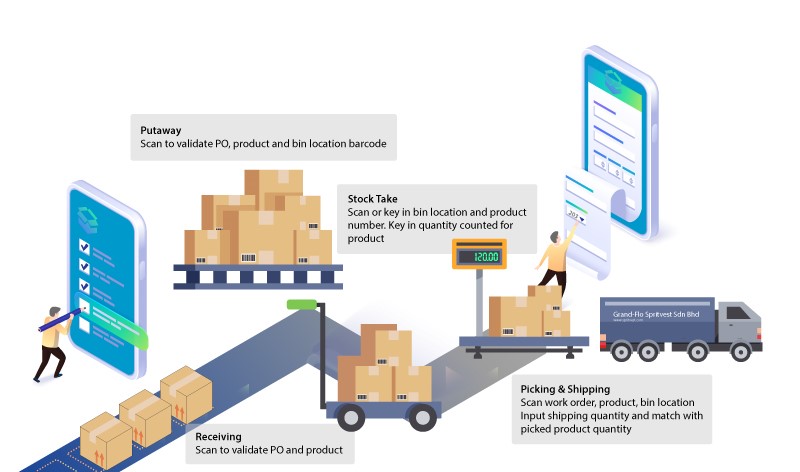

There are several different areas in a warehouse where you can implement an inventory system. These include the receiving area, the storage area, the packaging area, and the shipping area. Each area has its own unique set of requirements that must be met to optimise inventory levels and customer satisfaction.

The receiving area must be able to accurately track and receive shipments from suppliers. The storage area must be organised and efficient in order to optimise space and time. The packaging area must be able to accurately and efficiently package products for shipment. The shipping area must be able to ship products accurately and efficiently to customers.

Most of inventory control systems uses barcode, radio frequency identification (RFID) devices and inventory software as part of their inventory control system component. Barcode are the most commonly used in inventory control system and they are used by a variety of businesses, from small businesses to large retailers. RFID are mainly used by businesses that need to track high-value items or items that are difficult to keep track of such as clothing items.

No matter what type of business you have, there is an inventory control system that can help you keep track of your inventory and make sure that you always have the products that you need in stock.